FULLY AUTOMATIC PRE-FILL SYRINGE FILLING & STOPPERING SYSTEM SUITABLE FOR NESTED PRE-FILLABLE SYRINGES & NESTED STOPPERS, SEMI AUTOMATIC PRE FILL SYRINGE FILLING AND NESTED STOPPER

- 21CFR part 11 compliance

- Suitable for aqueous & viscous drugs

- Filling accuracy @ (+/-) 0.02ml in 0.2ml fill

- Fill volume spectrum : 0.2 ml to 10 ml (Change Part Supported)

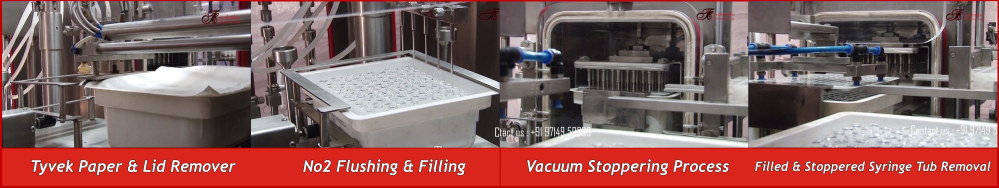

- Tub - in & Tub - out movement

- Synchronized LAF with Rabs/Isolator

| Series | Model no. | Refferal OutPut |

| KRISTAIN – II | HTE-PFS-A-02 | 15 to 20 PFS / Min. |

| KRISTAIN – III | HTE-PFS-A-05 | 40 to 50 PFS / Min. |

| KRISTAIN – IV | HTE-PFS-A-10 | 60 to 80 PFS / Min. |

Nest Type Prefilled Syringe and Stoppering Machine Manufacturer

An automated system for filling and stopping prefilled syringes is called Nest type prefilled syringe and stoppering machine and is used in pharmaceutical manufacturing industry. This type of equipment simplifies the manufacturing process by handling syringes stacked in holders or nests. A Nest type prefilled syringe and stoppering machine requires several critical processes to operate. Initially, empty needles are placed in nests and then carefully moved through the machine. With precision, the machine precisely administers medication into each syringe, guaranteeing precise fill levels. The device incorporates a stoppering mechanism to seal the syringes after filling. Maintaining the sterility and integrity of the drug within the syringes depends on this stoppering procedure. To avoid contamination and guarantee product quality, the machine runs under controlled circumstances throughout the duration of the procedure. Through an easy-to-use interface, operators may monitor the manufacturing process and make any adjustments to the Nest Type Prefilled Syringe and Stoppering Machine. The automation of the equipment lowers the possibility of human error and improves manufacturing process efficiency overall. To adhere to regulatory standards and Good Manufacturing Practices (GMP), Nest Type Prefilled Syringe and Stoppering Machines must undergo cleaning and maintenance procedures. To guarantee cleanliness and product safety, these machines can have sterilization-in-place (SIP) properties and are easy to clean. In conclusion, by automating the filling and stopping of prefilled syringes, a nest type prefilled syringe and stoppering machine plays an important role in pharmaceutical manufacturing. This technology supports the reliable production of injectables by improving manufacturing process efficiency, precision and sterility.